H13 Tool Steel: The Industry Standard for High-Temperature Tooling

In the domain of high-performance tooling, few materials have earned the trust and widespread usage of H13 tool steel. As hot work steel alloyed primarily with chromium, molybdenum, and vanadium, H13 has become the gold standard for tooling in hot forging, die casting, extrusion, and injection moulding industries.

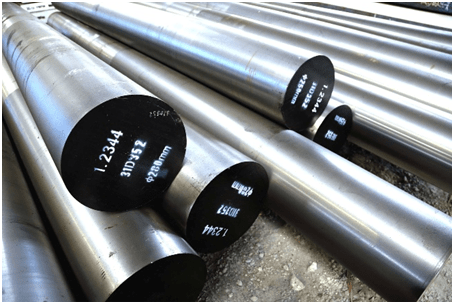

At Behari Lal Engineering, where metallurgical precision meets industrial reliability, we understand the value of this alloy—not just by specification, but by behaviour under stress, wear, and extreme thermal cycles. This blog delves into the properties, performance, and applications of H13 (DIN 1.2344 / SKD61) steel.

What is H13 Tool Steel?

H13, also known by international equivalents such as DIN 1.2344, SKD61, and X40CrMoV5-1, is a chromium-molybdenum hot work tool steel. Its claim to fame lies in its unique balance of thermal fatigue resistance, hot hardness, and abrasion resistance—making it ideal for moulds and dies operating at elevated temperatures.

H13 belongs to the air-hardening tool steel family and is extensively used for:

- Injection and compression moulds

- Die casting dies for aluminium and magnesium

- Extrusion dies and hot shear blades

- Forging dies, mandrels, and inserts

Key Properties of H13 Tool Steel

The performance of H13 stems from its alloy chemistry and its response to heat treatment. Here’s an improved and concise table summarizing its key mechanical and thermal properties:

Table: Technical Properties of AISI H13 Tool Steel

|

Property |

Value / Range |

|

Density (at 20°C) |

7.8 g/cm³ |

|

Melting Point |

1427°C |

|

Tensile Strength |

1590 MPa |

|

Yield Strength |

1380 MPa |

|

Reduction of Area |

50% |

|

Elastic Modulus |

215 GPa |

|

Poisson’s Ratio |

0.3 |

|

Thermal Conductivity |

17.6 W/m·K |

|

Coefficient of Thermal Expansion |

10.8 × 10⁻⁶ /K |

|

Machinability |

55% (Relative to W1 tool steel) |

|

Hardness (HRC, after tempering) |

Up to 56 HRC (varies by tempering temp) |

Heat Treatment and Hardness Response

H13 steel responds exceptionally well to heat treatment, which allows it to attain a wide range of hardness and toughness depending on the operating temperature. The table below illustrates how tempering temperature affects hardness:

Table: Hardness vs. Tempering Temperature for H13

|

Tempering Temperature (°C) |

Hardness (HRC) |

|

100 |

54 |

|

210 |

53 |

|

300 |

53 |

|

400 |

55 |

|

500 |

56 (Peak Hardness) |

|

550 |

54 |

|

600 |

51 |

|

650 |

43 |

|

700 |

34 |

Tempering around 500°C delivers the optimal combination of hardness and toughness, ideal for most die-casting and forging applications.

Chemical Composition of H13 Tool Steel

Table: AISI H13 Chemical Composition

|

Element |

Percentage (%) |

|

C |

0.45 |

|

Cr |

5.5 |

|

Mo |

1.75 |

|

V |

1.2 |

|

Si |

1.2 |

|

Ni |

0.3 |

|

Mn |

0.5 |

|

Cu |

0.25 |

|

P |

0.03 (max) |

|

S |

0.03 (max) |

Applications of H13 Steel

Owing to its exceptional high-temperature properties, H13 is found in nearly every toolshop and foundry environment:

- Injection Molds & Dies

Ideal for complex mould cavities and multi-cavity dies that operate under cyclic thermal loads. - Extrusion Dies & Mandrels

Maintains geometry and surface quality under the abrasive action of hotflowing metal. - Hot Forging Dies

High thermal shock resistance makes it reliable under repeated high-pressure impact. - Die-Casting Dies

Preferred for aluminium and zinc alloys due to excellent thermal conductivity and wear resistance. - Plastic Molds & Punches

Works well in precision plastic mould tools where polishability is critical.

Pros and Cons of AISI H13

Advantages

- Excellent combination of hardness and toughness

- Superior thermal fatigue resistance

- Good polishability and machinability

- Suitable for hot and cold work tooling

- Withstands repeated thermal cycling

Limitations

- Moderate corrosion resistance — not suited for aggressive environments

- Requires precise heat treatment to unlock full performance

- Limited weldability — prone to cracking without careful procedure

- More expensive than some general-purpose tool steels

Equivalent Grades Around the World

|

Country |

Standard |

Equivalent |

|

USA |

AISI/SAE |

H13 |

|

Germany |

DIN/WNr |

X40CrMoV5-1 |

|

Europe |

EN |

X40CrMoV5-1 |

|

China |

GB |

4Cr5MoSiV1 |

|

Japan |

JIS |

SKD61 |

|

South Korea |

KS |

STD61 |

|

Russia |

GOST |

4Ch4VMFS |

|

India |

IS |

XT35CrMoV1ST |

Final Thoughts

H13 tool steel remains a cornerstone in hot work tool applications, and at Behari Lal Engineeringwe ensure that every batch of H13 meets stringent quality standards—chemically, structurally, and mechanically.

Whether you're forging precision automotive parts, die-casting components, or shaping high-performance moulds, H13 gives you the thermal strength, hardness, and life cycle reliability your application demands.

Looking for reliable H13 tool steel from the best steel company in India?

Partner with Behari Lal Engineering for engineered excellence, every time.