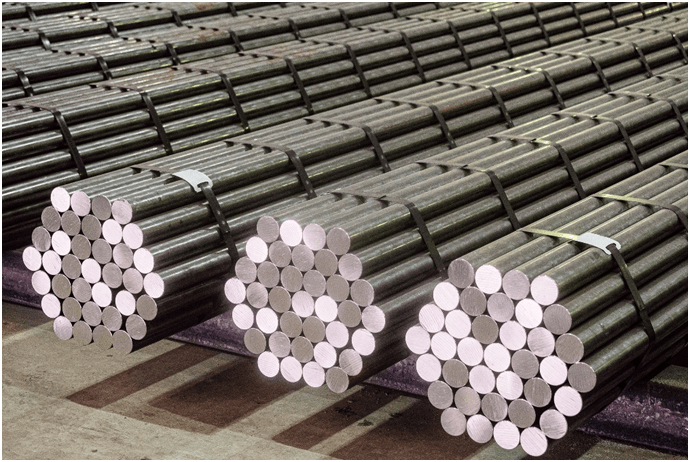

Round Steel Quenching: Engineering Strength Through Rapid Transformation

In the science of steel, strength is no accident—it’s engineered. At the heart of this engineering lies quenching, a heat treatment process that unlocks remarkable hardness and tensile strength. When applied to round steel products, quenching becomes a highly controlled operation, balancing internal structure with external demands.

At Behari Lal Ispat, our quenching practices are designed with precision—leveraging metallurgical expertise and advanced thermal systems to craft high-performance round steel for industrial excellence.

What Is Quenching?

Quenching is the rapid cooling of a metal after it has been heated to a high temperature (typically above its critical transformation range). The primary objective? To transform the microstructure, most often from austenite to martensite, the hardest and most brittle phase of steel.

This process is essential when the application demands:

- High surface hardness

- Increased tensile and yield strength

- Superior wear resistance

- Enhanced fatigue performance

Quenching modifies the internal crystal lattice structure, locking in a high-energy state that delivers exceptional mechanical properties.

Why Quench Round Steel?

When it comes to round bars, rods, or billets, the geometry plays a critical role. Unlike flat products, round steels require uniform penetration of cooling media—whether oil, water, or polymer emulsions—to prevent warping, internal stresses, and thermal shock.

Round steel quenching at Behari Lal Engineering ensures:

- Consistent hardness across the diameter

- Uniform phase transformation

- Crack-free cooling

- Enhanced core strength and surface toughness

Our quenching lines are optimized for cylindrical symmetry, allowing precise thermal gradients to form across cross-sections.

The Quenching Process: Step-by-Step

- Austenitization

The round steel is heated to 800–950°C, depending on alloy and carbon content. At this temperature, the steel becomes fully austenitic, a metastable face-centered cubic (FCC) structure. - Soaking Time Once the core reaches uniform temperature, it is held long enough to ensure full phase homogenization—critical for thick-sectioned round bars.

- Rapid Cooling The bar is quickly transferred to a quenching medium—usually oil or water, selected based on steel composition and end-use. This cooling transforms the microstructure from austenite to martensite, a body-centered tetragonal (BCT) phase known for its strength and hardness.

- Post-Quench Tempering(optional but recommended) To reduce brittleness, the quenched bar is often tempered at a lower temperature (150–600°C) to relieve stresses and fine-tune the mechanical profile.

Key Considerations in Round Steel Quenching

- Diameter vs. Cooling Rate: Larger diameters require more careful heat distribution and longer soak times to avoid incomplete transformation or internal cracking.

- Quenching Media Choice: Water provides rapid cooling but increases the risk of cracking in alloy steels. Oil and polymer solutions are more forgiving and allow better control for round profiles.

- Quench Cracks and Distortion: These are common in uncontrolled processes. At Behari Lal Ispat, our temperature control systems and part-specific quenching curves minimize risk while maximizing performance.

Applications of Quenched Round Steel

- Automotive axles and shafts

- Heavy-duty fasteners

- Die and tool components

- Industrial gears

- Construction anchor bolts

Wherever high strength and wear resistance are non-negotiable, quenched round steel delivers.

Metallurgical Precision at Behari Lal Engineering

Our facilities in Punjab, India, are designed to serve the evolving demands of global industries. Every quenched round bar undergoes microstructural analysis, hardness testing, and dimensional validation before dispatch.

We don’t just heat and cool—we understand the transformation. Our metallurgical team crafts the process curve for each grade and geometry, ensuring your steel performs not just in theory, but in the field.

Want steel that stands up to the toughest challenges?

Choose Behari Lal Engineering - where every quenched round bar is a product of metallurgical mastery and industrial foresight.