Alloy Steel Castings: Precision Engineering for Complex Shapes

By Behari Lal Engineering Limited Metallurgical Excellence Blog Series

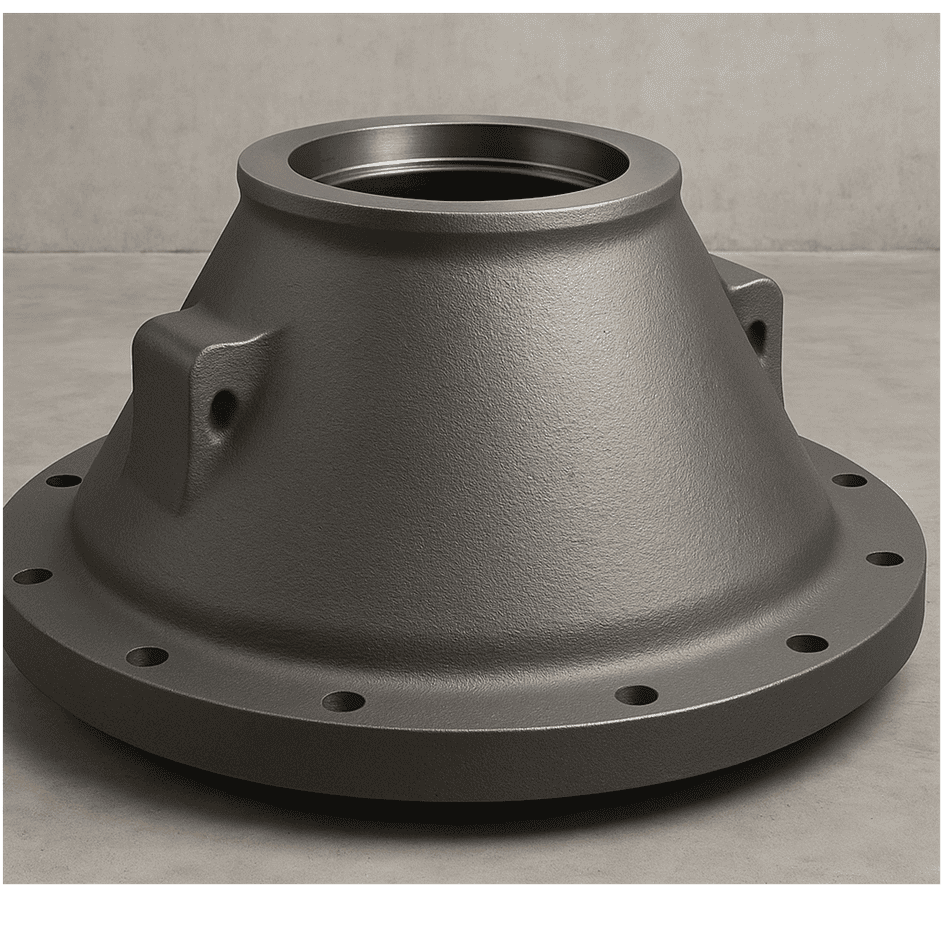

When strength needs form and complexity demands precision, alloy steel castings deliver. They are engineered to meet the structural, mechanical, and geometric demands of industries where failure is not an option. At Behari Lal Engineering Limited, we specialize in delivering high-quality alloy steel castings that meet the demanding requirements of various sectors across India.

What Are Alloy Steel Castings?

Alloy steel castings are components shaped by pouring molten alloyed steel into moulds to create near-net or net-shaped parts. Unlike forging or rolling, casting allows highly intricate geometries and internal cavities to be manufactured with minimal post-processing.

These castings offer a tailored combination of:

- High tensile strength

- Good corrosion and heat resistance

- Superior wear performance

- Design flexibility

Why Use Alloy Steel for Castings?

Alloy steels combine iron with elements like chromium, molybdenum, nickel, vanadium, and manganese to enhance properties such as toughness, strength, and corrosion resistance. The casting process further allows these properties to be tailored to specific service environments.

Advantages of Alloy Steel Castings

| Property | Benefit in Application |

|---|---|

| High Strength-to-Weight Ratio | Enables lightweight yet durable components |

| Excellent Toughness | Withstands shock loads and mechanical fatigue |

| Heat & Corrosion Resistance | Ideal for high-temp and aggressive chemical environments |

| Dimensional Accuracy | Precise control over complex shapes and internal features |

| Material Versatility | Grades can be customized for wear resistance, hardness, or ductility |

Common Grades & Industrial Applications

| Alloy Steel Grade | Typical Applications |

|---|---|

| ASTM A217 (WC6, WC9) | High-temperature valves, pump casings, pressure components |

| ASTM A487 Gr. 4C | Fracture-resistant parts in oil & gas and power sectors |

| ASTM A743 CA6NM | Corrosion-resistant pump impellers and housings |

| EN 10213 G17CrMo5-5 | Petrochemical and thermal power systems |

| IS 1030 (C45/50) | General engineering: levers, brackets, covers |

Casting Methods for Alloy Steels

At Behari Lal Ispat, we utilize multiple casting technologies based on part size, complexity, and application:

- Sand Casting

Best for large, heavy-duty parts like pump bodies and gear housings. - Lost Foam Casting

Ideal for high-precision components requiring intricate geometry.

Market Insight: India’s Rise in Alloy Steel Castings

India has emerged as a global hub for alloy steel castings, supported by a strong manufacturing base, cost-effective processes, and rising demand in sectors like energy, transportation, and defence.

📌 According to Mordor Intelligence, the Indian foundry market is expected to grow at over 10% CAGR, with alloy steel castings driving growth in power generation, oil & gas, and infrastructure projects.Our Expertise in Alloy Steel Castings

Behari Lal Ispat Private Limited stands as a leading manufacturer of engineering castings in India, catering to core industrial sectors such as steel, mining, railways, construction, power, automotive, paper, rubber, cement, and sugar industries.Our castings are available in both as-cast and fully machined conditions, with unit weights ranging from 500 kg to 15 metric tons.

Grades Offered

We offer a diverse range of alloy steel grades to suit various applications:

- IS 1030

- IS 2644

- IS 2707

- IS 2708

- IS 4896

- ASTM A216 WCB & WCC

- GS42CrMo4

- G20Mn5

- EN 24

- SS 410

- G10MnMoV6-3

- FG 250~300

- FCD 500~700

- among others

Industry Applications

Our alloy steel castings are integral to various industries:

| Industry | Component Examples |

|---|---|

| Steel Plants & Rolling Mills | Gear couplings, roll couplings, anvils, mill housings, bell & basin, reduction gears, hubs |

| Mining & Crushers | Mainframes, pitmans, toggle beams, bearing housings, flywheels, heads, bowls |

| Sponge Iron Industry | Kiln & cooler tyres, rollers, girth gears, bearing housings |

| Power Generation | Turbine castings, impellers, disc valves, runners (Francis & Pelton), hubs, yaw parts |

| Cement Plants | Tyres, support rollers, ball mill heads, trunnions, bearing housings, diaphragms |

| Sugar Industry | Crown pinions, headstocks, couplings, trash beams, caps, gears, sprockets, hubs |

| Oil & Gas | Pressure vessels, fracturing heads, valve bodies (WCB/WCC grades) |

| Defense& Railways | Armoured vehicle parts, brake housings, couplers, traction components |

| Automotive & Transport | Differential cases, structural brackets, hubs |

| General Engineering | Heavy earthmoving components, star gears, adjustment rings, gear blanks |

| Construction | Machinery parts, wear-resistant fittings, custom structural castings |

| Paper & Rubber | Specialty housings, supports, and abrasion-resistant rollers |

Manufacturing Capabilities

Our comprehensive casting process encompasses engineering, pattern making, moulding, heat treatment, fettling, and machining.With advanced infrastructure and a skilled workforce, we ensure high-quality castings that meet stringent industry standards.

Commitment to Quality

At Behari Lal Engineering Limited, we are committed to delivering superior products that exceed customer expectations.Our ISO 9001:2015 certified processes and dedicated quality assurance team ensure that every casting meets the highest standards of excellence.

Heat Treatment Expertise

Our in-house facilities allow us to perform normalizing, quenching & tempering, annealing, and stress relieving to enhance mechanical properties such as hardness, ductility, and toughness—customized to meet specific service conditions.

Non-Destructive Testing (NDT)

We provide full non-destructive testing services including ultrasonic testing (UT), magnetic particle inspection (MPI), and liquid penetrant testing (LPT) to ensure integrity and reliability for critical components.

Why Choose Behari Lal Engineering Limited?

- 100+ years of legacy

- Up to 15 metric tons casting capacity

- Fully integrated in-house machining and heat treatment

- ISO 9001:2015 certified quality assurance

- Global export capability with custom specifications

- Full NDT and material testing support

- Rapid turnaround times and responsive customer service

Looking for reliable alloy steel castings in India?

Partner with Behari Lal Engineering Limited —where precision meets performance.

SEO Tags & Keywords

alloy steel castings India, custom alloy steel casting manufacturer, industrial steel castings, ASTM A217 castings, EN 10213 foundry, high strength steel castings, heavy engineering castings India, machined alloy castings, BLEL castings, oil and gas steel castings supplier