Everything You Need to Know About 42CrMo4 Alloy Steel

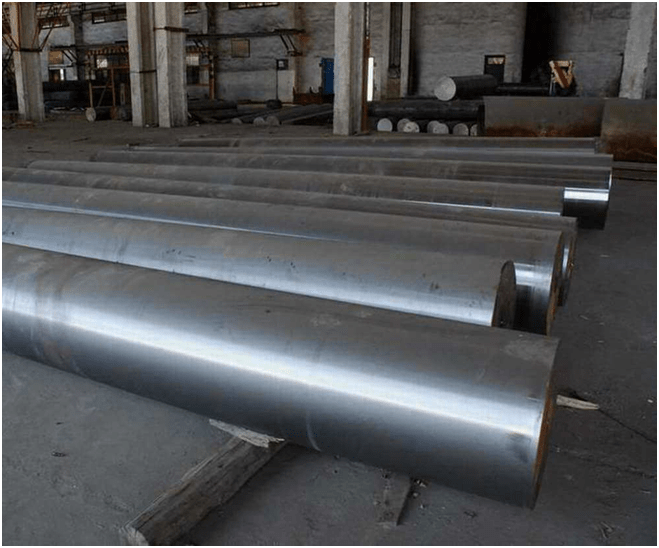

When strength meets precision and performance demands reliability under extreme stress, few materials rise to the challenge like 42CrMo4 alloy steel. At Behari Lal Engineering, a leading 42CrMo4 alloy steel manufacturer, we supply this versatile grade in forged, rolled, and machined formats to meet the rigorous standards of automotive, energy, and heavy machinery industries.

When Strength Meets Precision: The Power of 42CrMo4 Alloy Steel

In industries where precision is paramount and reliability is non-negotiable, few materials meet the challenge like 42CrMo4 alloy steel. Known for its excellent mechanical properties and adaptability to demanding applications, this high-performance steel is trusted across automotive, energy, and heavy engineering sectors.

At Behari Lal Engineering Limited (BLEL), a leading 42CrMo4 alloy steel manufacturer in India, we supply this versatile grade in forged, rolled, and machined formats, customized to client specifications and global standards.

What Is 42CrMo4 Alloy Steel?

42CrMo4 is a chromium-molybdenum (Cr-Mo) alloy steel, classified under the EN 10083-3 standard. Its superior hardenability, toughness, and fatigue resistance make it ideal for components subjected to dynamic, torsional, or impact stress.

International Equivalents:

- DIN 1.7225

- AISI 4140 (close equivalent)

- ASTM 42CrMo4 +QT

This steel is widely used in quench and tempered (QT) condition to enhance its strength and durability.

Chemical Composition of 42CrMo4

| Element | Content (%) |

|---|---|

| Carbon (C) | 0.38 – 0.45 |

| Chromium (Cr) | 0.90 – 1.20 |

| Molybdenum (Mo) | 0.15 – 0.30 |

| Silicon (Si) | 0.20 – 0.40 |

| Manganese (Mn) | 0.60 – 0.90 |

| Sulfur (S) | ≤ 0.035 |

| Phosphorus (P) | ≤ 0.035 |

Mechanical Properties (After QT Treatment)

| Property | Typical Value |

|---|---|

| Tensile Strength | 900–1100 MPa |

| Yield Strength | ≥ 650 MPa |

| Elongation at Break | 13–16% |

| Impact Toughness (ISO-V) | > 40 J at -20°C |

| Hardness (HRC) | 28–34 (as quenched and tempered) |

| Modulus of Elasticity | 210 GPa |

| Density | 7.85 g/cm³ |

Why Choose 42CrMo4 Alloy Steel?

- High Strength & Yield

Ideal for components under extreme torsional or static load. - Outstanding Toughness

Performs reliably under shock loads and low temperatures. - Excellent Hardenability

Enables consistent properties across large-diameter parts. - Superior Fatigue Resistance

Crucial for rotating and dynamically stressed components. - Good Machinability

Balanced mechanical strength and workability in QT condition.

Applications Across Industries

| Sector | Common Uses |

|---|---|

| Automotive | Crankshafts, camshafts, gear shafts, axles |

| Oil & Gas | Tool joints, rotary shafts, drill collars |

| Heavy Machinery | Forgings, gear blanks, hydraulic components |

| Power Generation | Turbine bolts, couplings, forged rotors |

| Construction | Lifting pins, cylinders, mechanical joints |

| Railway & Defence | Traction gearboxes, connecting rods, frames |

Heat Treatment of 42CrMo4 Steel

BLEL offers customized QT treatment based on application needs, with precise control of time and temperature.

| Process | Temperature (°C) | Cooling Medium |

|---|---|---|

| Annealing | 680–710 | Furnace cooled |

| Normalizing | 850–880 | Air |

| Quenching | 840–880 | Oil or water |

| Tempering | 540–680 | Air |

Our in-house thermal treatment systems ensure uniformity and repeatability—critical for safety and fatigue resistance.

Industry Insight: Rising Demand for Cr-Mo Steels

📈 Global demand for Cr-Mo alloy steels like 42CrMo4 is projected to grow significantly by 2030, driven by:

- Adoption of EV drivetrain components

- Pressure vessels for renewable energy projects

- Expansion of railway and defense infrastructure

With India emerging as a global forging hub, BLEL is at the forefront of meeting this material demand.

Why BLEL for 42CrMo4 Alloy Steel?

As a top-tier Indian manufacturer of 42CrMo4 steel, BLEL offers:

- Forged, hot-rolled, and peeled bars in multiple profiles

- ISO-certified quench and temper facilities

- Ultrasonic testing for internal soundness

- Custom mechanical properties as per engineering drawings

- Expert metallurgical consultation and after-sales support

Conclusion

42CrMo4 alloy steel is not just a material—it’s a strategic choice for high-performance engineering. Whether you're manufacturing critical rotating parts, pressure components, or structural shafts, 42CrMo4 offers the strength, ductility, and fatigue resistance your project demands.

Looking for a reliable 42CrMo4 alloy steel manufacturer?

Trust Behari Lal Engineering Limited (BLEL)—where precision metallurgy meets industrial reliability.

Tags/Keywords:

42CrMo4 alloy steel India, 42CrMo4 manufacturer, QT steel supplier, chromium molybdenum steel, forged alloy steel bars, heat-treated alloy steel, BLEL, EN 10083-3 42CrMo4, AISI 4140 equivalent, Cr-Mo steel India